Practical implications for stakeholders

In order to make the manufacturing process of milk powders more efficient, this project aimed to better understand the relationship between milk functionality and farming factors.

High quality milk powders require milk with appropriate heat stability and behaviour during concentration. The ability to control the heat stability and concentration characteristics of milk would give manufacturers the ability to make powders more efficiently.

As the major consumer of energy in dairy processing, and with a predicted 45% increase in world energy demand by 2030, milk powder processors will benefit from any research that might help them to reduce the extent to which energy costs affect their business.

For the scientifically minded

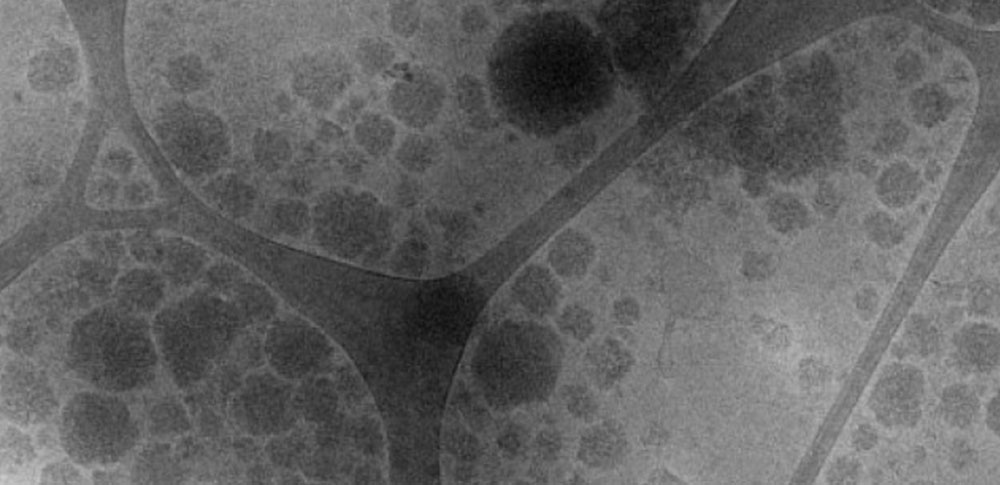

This project explored whether the key functionalities of milk, particularly heat stability and concentrate properties, were determined by cow genetics and diet, via a link to the size and stability of casein micelles.

It appears that cow genetics determine casein micelle size, with large variation observed between cows.

The relative size of casein micelles in a given cow is constant throughout the milking season and across consecutive lactations. Different feeding strategies do not affect casein micelle size.

Low heat-treated milk (72°C) with large micelles could be evaporated to higher total solids with lower viscosities than milk with small micelles. That is at a given high viscosity (100mPa.s) a concentrate made from large micelles will have 4% higher concentration than one made from small micelles.

Based on published modelling (Fox et al. 2010), an increase of 4% in the level of solids in the dryer could equate to a 10-12% saving in energy requirements for spray drying milk powder.

Small micelle milks have alternate favourable attributes including superior heat stability and renneting characteristics.

How does the industry benefit?

The knowledge generated from this project may assist farmers and herd selection programs to maximize the performance of their milk through cow selection. Alternatively, milk processing plants could exploit the variation in milk micelle size by accordingly targeting milks for certain dairy products to increase processor efficiency and maximise product quality.

Project details

Project date: Aug 2010 to July 2013

Key external stakeholders: Dairy farmers, dairy farm service providers, dairy processors

Partner organisations: CSIRO Animal, Food and Health Sciences Division; DEPI

Project identifier: INN-11-012

GDF Contribution: $253,330